Wind energy is considered a safe, low-emission and inexpensive power source and thus a key driver of the energy system transition process. Experts expect a significant expansion of capacities especially in North America*. As a result, transport needs are undergoing a significant increase. Wind turbine components must be transported to the place of use from production sites and intermediate storage facilities. At the TII Group subsidiaries, customers can find the right transport solution for each of these components.

Tax benefits for new wind turbines and ambitious government sourcing goals for electricity from wind energy have given the North American wind energy industry a major boost. Offshore plants, which are particularly powerful and feature correspondingly large components, are also expected to increasingly contribute to the generation of electricity from renewable sources. In addition to the components required for generating energy such as the rotor blades, star and hub, tower segments, machine housing and the so-called nacelles, the anchoring used to secure the towers to the seabed must be moved onto the transport barges and then taken to the designated location at sea. This includes gravity foundations made of concrete, steel tripods and monopiles. Transition pieces also feature: connecting elements that securely fix the installation to the foundations.

Transporting the sensitive and immensely heavy components of wind turbines requires vehicles that are functional and safe as well as stable as those produced by SCHEUERLE and KAMAG, subsidiaries of the Transporter Industry International Group (TII Group). Notwithstanding the wide range of dimensions and weights of installation components to be moved, transportation companies can always find the most appropriate transport solution at SCHEUERLE and KAMAG – naturally always with the quality promise “Made in Germany”. In particular, SPMTs (Self Propelled Modular Transporters) and modular platform vehicles are ideally suited for use in the wind energy sector. They are freely scalable and can therefore be adapted to accommodate any load.

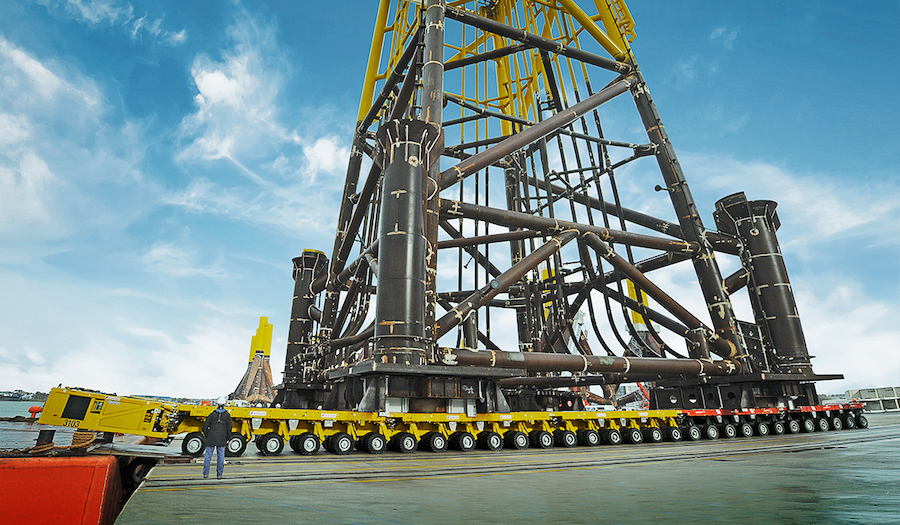

SPMT – the smart all-rounder for transporting the heaviest of components

The transport modules of the SPMT series are suitable for transporting the largest and heaviest components. Handling gravity foundations, tripods and nacelles is child´s play for these powerful transport platforms. Due to the diverse combination options provided by the SPMT axle lines, SPMT vehicle configuration payloads are theoretically unlimited. Likewise, the cantilevering dimensions of the components do not pose any problems for SPMT platforms. SPMT modules also safely transport components featuring complex geometries such as tripods when electronically coupled in a loose coupling mode configuration. Thanks to the wide range of accessories, SPMT can be used extremely versatilely. Tower segments, for example, can be transported directly on the platform itself or with the help of special adapters and boiler decks. Vehicles from the TII Group are already used during the construction process of plant components: for example, in production logistics as an “assembly line” and for transporting between different manufacturing locations. Here too, the self-propelled and modular transporters of the SPMT or SPMT PowerHoss series are the first choice.

Market leader´s technology means maximum flexibility for customers

SCHEUERLE developed the SPMT back in the early 1980s. Today, the self-propelled vehicles of the SPMT series are best sellers due to their extraordinary qualities and no other manufacturer has more comparable axle lines on the market than SCHEUERLE. The wide distribution of SPMT axle lines means an extremely high level of flexibility for customers in addition to the problem-free procurement of the axle lines via SCHEUERLE´s worldwide sales network together with the comprehensive service. Due to the widespread use across other fleets, SPMT axle lines can also be rented at very short notice (cross-hire rental) in order to cover peak demands.

InterCombi SP/SPE is a cost-effective addition to the vehicle fleet

The self-propelled platform vehicles of the InterCombi SP/SPE series are, in turn, best suited to transport loads with proportionally simple geometry and high unit weights such as monopiles on-site. Their advantage of this series lies not only in the low and robust construction but also in the sophisticated and precise control technology. The InterCombi SP/SPE is the cost-effective addition in order to be able to create self-propelled transport units with existing InterCombi vehicles as coupling operations are guaranteed problem-free.

Large selection of transport solutions for rotor blades

Rotor blades are a particularly sensitive load. Today, lengths of 80 meters and more are nothing unusual. Using TII Group vehicles, they can be safely and economically transported in various ways. With the rotor blade adapter, even the most difficult sections of a route can be easily mastered. The system is suitable for all platform vehicles and self-propelled vehicles of the TII Group such as the SPMT and InterCombi as well as the K24 and K25. With the help of this adapter, loads can be raised up to an angle of 70 degrees while driving and can be rotated endlessly around its own axis to move it safely around obstacles. The latest generation achieves sufficient load torque in order to transport all commonplace rotor blades.

TII Group vehicles stand for excellent maneuverability

The transport of components for onshore installations places additional demands on vehicle technology. In this respect, the infrastructure often presents the greatest challenge. Passing through narrow streets and negotiating obstacles such as buildings and trees, even the most bulky components have a destination that must be reached. The versatile, self-propelled platform vehicles from the SPMT and InterCombi series from SCHEUERLE and K25 from KAMAG are also suitable transport solutions for these assignments. The proven pendulum axle technology ensures a high level of stability and, thanks to the large steering angle, great maneuverability too.

Decades of experience facilitate extensive customer assistance

Especially in the field of wind energy where new technologies are constantly emerging and components are continuously increasing in size, providing in-depth advice to the customer is part of the manufacturer’s requirement specifications. The market knowledge and expertise that the TII Group has built up over decades is also paying dividends. With the forward-looking transport solutions from SCHEUERLE, customers will remain extremely competitive in the future. For TII Group vehicles as well as for the wind energy industry, the motto is: The sky is the only limit!

SCHEUERLE successful on US market for over 50 years

SCHEUERLE´s continuing success story in the USA is one that stretches back over decades. The special vehicle manufacturer´s products have been available on the American continent for 50 years now. Innovative strength and manufacturing quality “Made in Germany” has convinced many customers in the United States. Today, SCHEUERLE is one of the leader in the US market in the shipyard transporter segment, the self-propelled modular transport platforms from the SPMT series and special vehicles for the aerospace industry. Well-known customers include the space company United Launch Alliance (ULA) as well as Bragg Crane Service and Omega Morgan in the wind power sector.

*Background: Wind power in North America

In 2019, the total capacity of electricity from wind energy worldwide reached 651 gigawatts (GW), an increase of more than 60 GW compared to 2018 (+10 percent). Today, onshore installations generate the largest share of wind energy. Last year, its total capacity increased by 54.2 to 621 GW while the capacity of offshore plants grew by 6.1 to 29 GW. North America in particular is experiencing a strong expansion of wind energy plants thanks to the Production Tax Credit (PTC) and ambitious government sourcing goals. In a worldwide comparison, North America is already in second place regarding the creation of wind energy capacity. Here, the total capacity of onshore wind power grew by 9.1 to 105.4 GW in the past year. The offshore sector currently generates only 30 megawatts (MW) and thus offers huge opportunities. Experts in this segment expect a great deal of activation stimulus from the available support measures. The National Renewable Energy Lab (NREL) has calculated a potential of 2,000 GW of offshore wind energy, twice as much as the current US electricity consumption. At present, more than 15 offshore projects are being planned. Construction is expected to be completed by 2026.

Sources: Global Wind Energy Council (GWEC), American Wind Energy Association (AWEA). GWEC estimates (excluding the effects of Covid19) as of March 2020.